- 713.590.1312

- sale@pandbtools.com

Innovative Approaches to Using Best Steam Valves in Industrial Applications

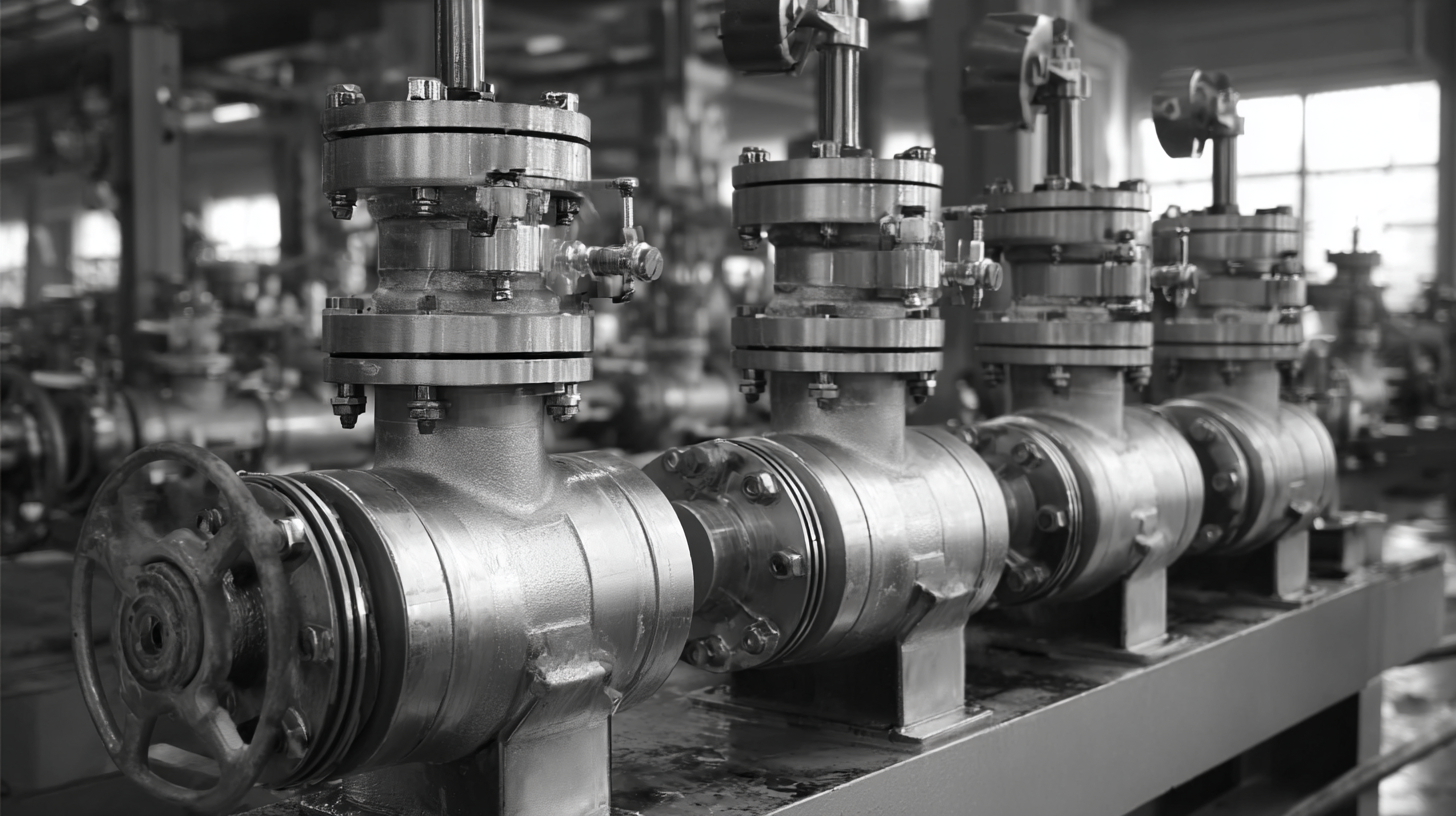

In the ever-evolving landscape of industrial applications, the importance of steam valves cannot be overstated. As industries move towards 2025, innovative approaches to the use of steam valves are becoming pivotal in enhancing efficiency, safety, and sustainability in operations. This blog will explore the latest technological trends reshaping the industry, with a focus on how top strategies are being implemented to optimize the functionality of steam valves.

In the ever-evolving landscape of industrial applications, the importance of steam valves cannot be overstated. As industries move towards 2025, innovative approaches to the use of steam valves are becoming pivotal in enhancing efficiency, safety, and sustainability in operations. This blog will explore the latest technological trends reshaping the industry, with a focus on how top strategies are being implemented to optimize the functionality of steam valves.

By examining cutting-edge designs and novel materials, we aim to shed light on the best practices that industries can adopt to leverage steam valves effectively. As we delve into these advancements, readers will gain valuable insights into how integrating modern steam valve technologies can drive operational excellence and foster innovation in their respective fields.

Understanding the Role of Steam Valves in Modern Industrial Processes

In modern industrial processes, steam valves play a critical role in regulating the flow and pressure of steam throughout various systems. These valves are essential components in applications ranging from power generation to food processing, influencing not only operational efficiency but also safety and product quality. By controlling steam flow, these devices ensure optimal performance, enabling businesses to maintain a competitive edge while minimizing energy consumption and downtime.

Innovative approaches to steam valve design and application have emerged, particularly in the realm of automation and smart technologies. Advanced steam valves now incorporate features like remote monitoring and automated control, allowing for real-time adjustments and predictive maintenance. This technological evolution not only enhances operational reliability but also provides industries with invaluable data, enabling process improvements and reducing the risk of steam-related failures. As industries continue to embrace these innovations, understanding the pivotal role of steam valves becomes increasingly essential for optimizing industrial processes.

Innovative Approaches to Using Best Steam Valves in Industrial Applications

This chart illustrates the performance metrics of steam valves used in modern industrial processes. It highlights critical parameters such as temperature, pressure, flow rate, and overall efficiency, providing insight into the effectiveness of innovative steam valve technology.

Key Features and Benefits of Advanced Steam Valve Technologies

In the realm of industrial applications, the use of advanced steam valve technologies is transforming operational efficiency and safety. Key features of these modern steam valves include precision control, enhanced durability, and improved energy efficiency. These valves are designed to handle high pressures and temperatures, making them ideal for processes in power generation, food processing, and chemical manufacturing. By employing smart materials and innovative designs, these valves ensure a tight seal, minimizing leaks and maximizing performance.

Tip: When selecting steam valves, consider those equipped with automated monitoring features. These not only streamline operations but also allow for real-time data analysis, helping to prevent potential issues before they arise.

Another significant benefit of advanced steam valve technologies is their ability to reduce maintenance costs. With features such as self-diagnostics and remote accessibility, these valves provide operators with vital information that allows for timely repairs and replacements. Additionally, many modern valves come with a longer lifespan, which translates to cost savings in both replacement and maintenance efforts.

Tip: Regularly assess your steam valve configuration to optimize efficiency. By analyzing performance data, you can identify areas for improvement and ensure that your systems operate at peak efficiency.

Innovative Applications of Steam Valves Across Various Industries

In various industries, steam valves play a crucial role in regulating pressure and controlling the flow of steam. Innovations in steam valve technology have opened new avenues for their application across sectors such as food processing, pharmaceuticals, and energy production. For instance, in the food industry, steam valves are integral to processes that require precise temperature control for sterilization and cooking. The latest designs allow for enhanced efficiency and reduced energy consumption, making them an excellent choice for environmentally conscious operations.

When selecting steam valves for your applications, consider the following tips: First, ensure that the valve materials are compatible with the steam quality and other substances in the system. This will help prevent corrosion and extend the lifespan of your equipment. Second, look for valves with advanced features, such as smart control systems that enable real-time monitoring and adjustments, improving operational efficiency.

Additionally, in the pharmaceutical sector, steam valves are essential for maintaining stringent hygiene standards during the production of medications. By implementing steam valves equipped with automation capabilities, manufacturers can reduce human error and optimize production workflows. As industries continue to evolve, the innovative use of steam valves is set to transform operational processes and increase overall productivity.

Best Practices for Selecting and Integrating Steam Valves in Operations

Selecting the right steam valves for industrial applications is crucial for optimal performance and efficiency. When integrating steam valves into your operations, it is essential to consider several factors, such as the pressure and temperature ratings of the steam system, the compatibility of the materials, and the operational environment. By carefully assessing these variables, you can ensure that the steam valves you select can withstand the demands of your system while minimizing the risk of leaks and failures.

Tip: Always consult manufacturers’ specifications and guidelines before making a purchase. This will give you insight into the valve’s capabilities and expected lifespan, helping you make an informed decision.

Another important aspect is the installation and maintenance process. Proper installation of steam valves is key to preventing operational issues. Make sure that the valves are installed according to manufacturer recommendations and industry standards, and regularly check for signs of wear or malfunction.

Tip: Implement a routine maintenance schedule that includes inspection and testing of steam valves to identify potential problems early. This proactive approach not only enhances reliability but also prolongs the life of your equipment.

Future Trends in Steam Valve Development and Sustainability Practices

As industries strive towards greater efficiency and sustainability, the development of steam valves is undergoing significant transformation. The global steam valve market is projected to grow from USD 3.4 billion in 2023 to USD 4.7 billion by 2028, reflecting a CAGR of 6.5%. This indicates a strong demand for innovative technologies that enhance both performance and environmental sustainability. Future trends indicate a shift towards smart steam valves equipped with IoT technology, allowing for real-time monitoring and predictive maintenance, ultimately reducing downtime and optimizing energy consumption.

Tip: When selecting steam valves, consider those that feature materials designed for longevity and corrosion resistance, as they contribute significantly to reducing operational costs and environmental impact. Additionally, look for valves that adhere to sustainable manufacturing practices.

Moreover, the integration of sustainable practices in steam valve production is gaining traction. Emphasizing the use of recycled materials and energy-efficient manufacturing processes not only meets industry regulations but also appeals to environmentally conscious consumers. According to a recent report by MarketsandMarkets, 72% of manufacturers are now focusing on sustainable product development, showcasing that sustainability is no longer an option but a necessity in the industry.

Tip: Regularly evaluate your steam valve systems for opportunities to upgrade to more energy-efficient models. This proactive approach not only enhances your operations but also aligns with global sustainability goals.