- 713.590.1312

- sale@pandbtools.com

Innovations in Best Stainless Steel Ball Valves for 2025 Industry Trends and Future Solutions

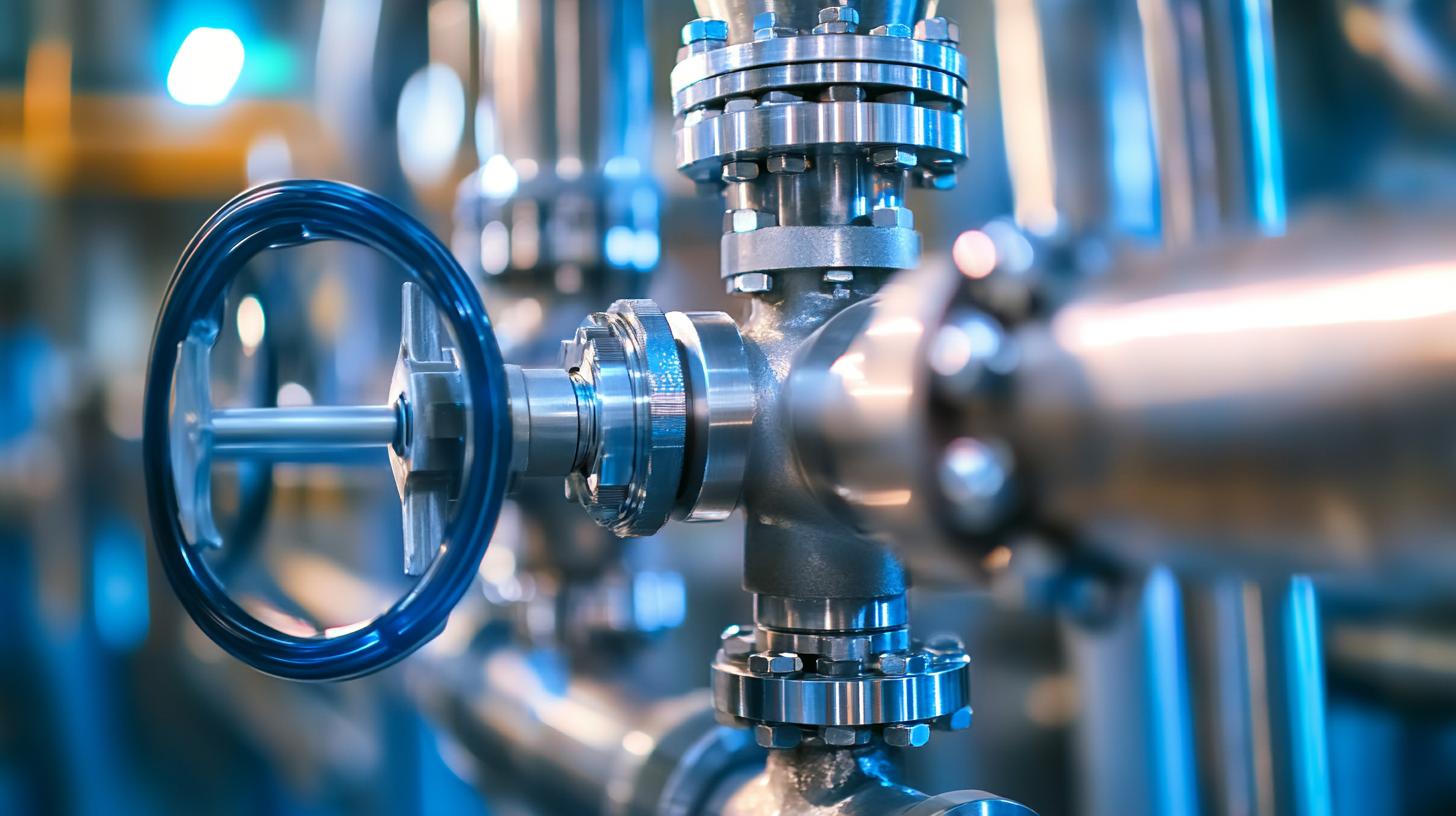

In the rapidly evolving landscape of industrial solutions, the innovations surrounding Stainless Steel Ball Valves are set to redefine operational efficiency and reliability in 2025. As industries place increasing emphasis on durability, performance, and sustainability, the latest advancements in these essential components promise to meet the diverse needs of modern applications.

From enhanced corrosion resistance to smart technology integration, the future of Stainless Steel Ball Valves is characterized by a commitment to improved functionality and adaptability. This tutorial aims to explore the emerging trends and cutting-edge solutions that will influence the design and utilization of these valves in various sectors. By examining the anticipated advancements, industry professionals can better prepare to harness the full potential of Stainless Steel Ball Valves, ensuring optimal performance and longevity in their projects.

Key Features of Advanced Stainless Steel Ball Valves for 2025

As industries continue to evolve, the demand for advanced stainless steel ball valves is on the rise. In 2025, key features are likely to redefine their use across sectors like oil and gas, water treatment, and manufacturing. One of the prominent trends is the integration of smart technologies into valve designs. These innovations enable real-time monitoring and predictive maintenance, significantly enhancing operational efficiency and reducing downtime.

Another essential feature is the development of enhanced sealing mechanisms. Innovations in materials and design are leading to improved leak prevention and greater durability under extreme pressure and temperature conditions. Manufacturers are also focusing on sustainability by employing eco-friendly materials and processes, aligning with global environmental standards. Such advancements not only improve valve performance but also contribute to a greener future in industrial operations.

Emerging Trends in Stainless Steel Ball Valve Design and Manufacturing

The landscape of stainless steel ball valve design and manufacturing is evolving rapidly, driven by the increasing demand for efficiency, sustainability, and advanced technology. In 2025, we can expect to see a focus on smart valve solutions that leverage IoT technology, allowing for real-time monitoring and automated control. This shift not only enhances operational efficiency but also facilitates predictive maintenance, reducing downtime and operational costs for industries.

Moreover, the integration of advanced materials and innovative manufacturing techniques is set to redefine the industry standards. Techniques such as 3D printing are enabling manufacturers to produce complex valve designs with reduced waste and shorter lead times. Additionally, the emphasis on environmentally friendly production methods will lead to the use of recycled materials and sustainable practices in the manufacturing processes. As these trends continue to develop, stakeholders in the industry must stay ahead by embracing these innovations to ensure competitiveness and sustainability in their operations.

Sustainability Practices Impacting Stainless Steel Ball Valve Production

Sustainability has become a central theme in the manufacturing of stainless steel ball valves, shaping industry practices and influencing product design. As the demand for environmentally friendly solutions continues to rise, manufacturers are increasingly adopting green practices in their production processes. This includes the use of recycled materials, which not only minimizes waste but also reduces the energy consumption associated with sourcing new raw materials. The industry is also moving towards employing renewable energy sources in the production cycle, further enhancing their commitment to sustainability.

Moreover, innovations in stainless steel ball valves are reflecting this shift toward sustainability. For instance, designs that incorporate fewer components reduce the environmental footprint during both production and installation. Advanced technologies such as precision machining and 3D printing are being utilized to optimize material usage, thereby minimizing waste while maintaining performance standards. These innovations not only adhere to sustainability practices but also cater to evolving customer preferences for durable and eco-friendly products, ensuring that the stainless steel ball valve sector is prepared to meet the challenges of 2025 and beyond.

Innovations in Best Stainless Steel Ball Valves for 2025

This chart illustrates the projected trends in key features of stainless steel ball valves leading up to 2025, showcasing advancements in sustainability practices and their impact on production.

Future Technologies Driving Innovation in Ball Valve Functionality

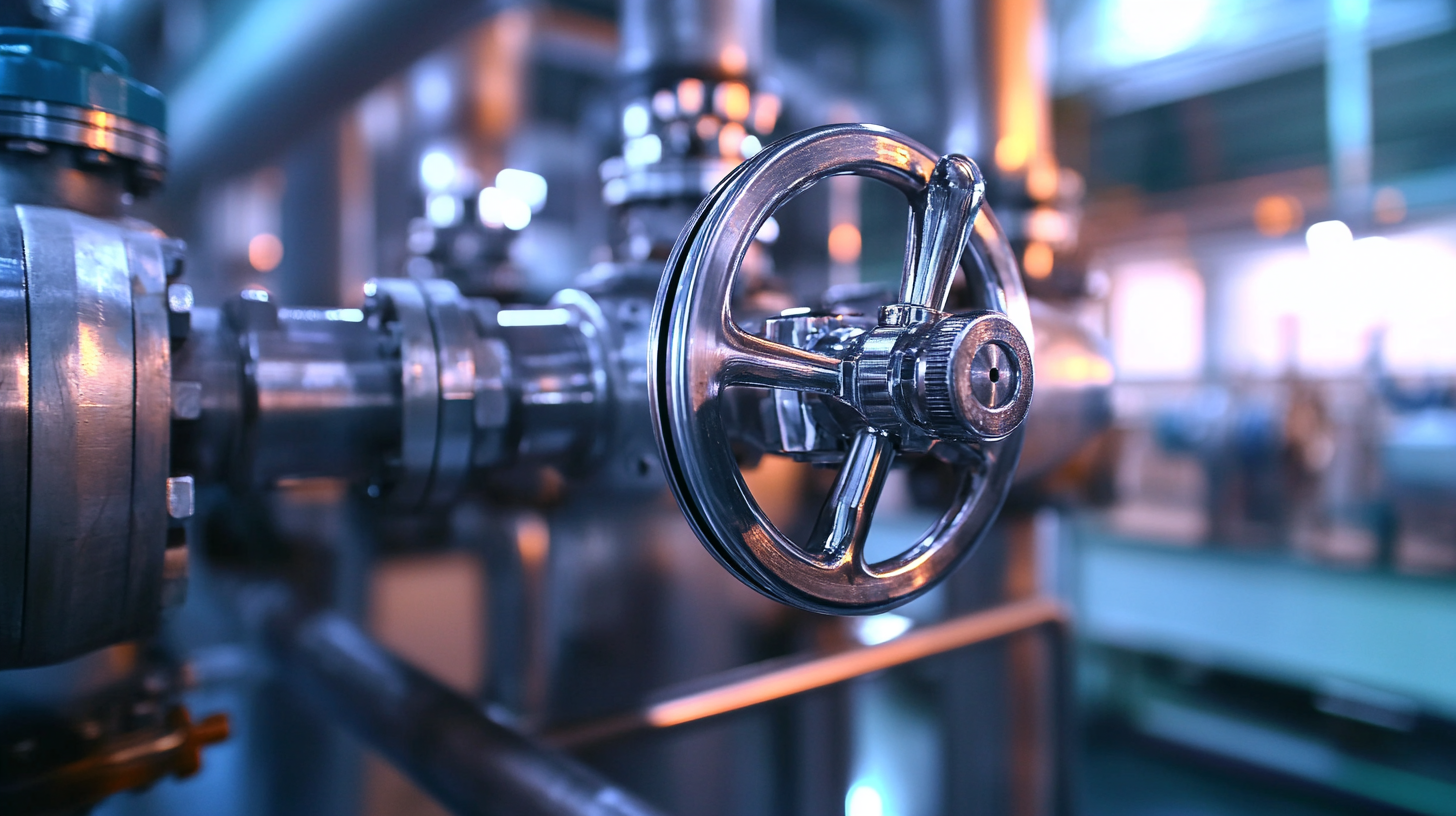

As the demand for high-performance solutions in various industrial applications continues to rise, the innovations in stainless steel ball valves are poised to play a crucial role in 2025 and beyond. Future technologies are driving significant advancements in ball valve functionality, enhancing their efficiency, reliability, and adaptability. One prominent trend involves the integration of smart technologies, such as IoT sensors and automation systems, which enable real-time monitoring and control. This will not only streamline operations but also facilitate predictive maintenance, greatly reducing downtime.

Moreover, the focus on sustainable practices is prompting manufacturers to innovate in materials and designs. The development of eco-friendly coatings and corrosion-resistant alloys will extend the lifespan of ball valves, ensuring they can withstand demanding environments while minimizing environmental impact. Flexible designs that allow for easier installation and maintenance are also becoming increasingly important. By embracing these future technologies, the industry is setting the stage for more effective and sustainable solutions in ball valve applications, ensuring that they meet the evolving needs of markets globally.

Essential Considerations for Selecting the Right Stainless Steel Ball Valve

When selecting the right stainless steel ball valve, there are several essential considerations to keep in mind. Firstly, the application environment plays a significant role in determining the type of valve best suited for your needs. Factors such as temperature, pressure, and the nature of the fluid being regulated must all be evaluated. It’s crucial to choose a valve that can withstand the operational parameters without compromising performance or safety.

Tip: Always review the valve’s pressure rating and temperature limits in the manufacturer's specifications to ensure compatibility with your system.

Another important consideration is the valve size and connection type, which must match the existing piping system. An improperly sized valve can lead to inefficiencies or even failure under operational conditions. Additionally, the type of connection—be it flanged, threaded, or welded—should align with the installation requirements of your project.

Tip: Utilize a sizing chart and consult with engineers to select the appropriate valve dimensions, ensuring a secure and leak-proof installation. By addressing these factors, you can make informed decisions that enhance the performance and longevity of your stainless steel ball valve.

Innovations in Best Stainless Steel Ball Valves for 2025 Industry Trends and Future Solutions - Essential Considerations for Selecting the Right Stainless Steel Ball Valve

| Valve Type | Size Range (inches) | Pressure Rating (psi) | Temperature Range (°F) | Applications | Key Innovations |

|---|---|---|---|---|---|

| Standard Ball Valve | 1 - 6 | 150 - 300 | -40 to 250 | Water, Oil, Gas | Enhanced sealing technology |

| Full Port Ball Valve | 2 - 8 | 200 - 600 | -20 to 400 | Chemical Processing | Corrosion-resistant coatings |

| Trunnion Mounted Ball Valve | 4 - 24 | 150 - 1500 | -40 to 450 | Oil & Gas, Power Generation | Advanced actuator designs |

| Multi-port Ball Valve | 1 - 4 | 150 - 300 | -30 to 250 | Wastewater Treatment | Compact design for space savings |

| Electric Ball Valve | 0.5 - 6 | 100 - 300 | -20 to 200 | HVAC, Water Control | Smart control integration |