- 713.590.1312

- sale@pandbtools.com

Comparative Analysis of the Top 5 Best Swing Check Valves: Efficiency and Performance Metrics Revealed

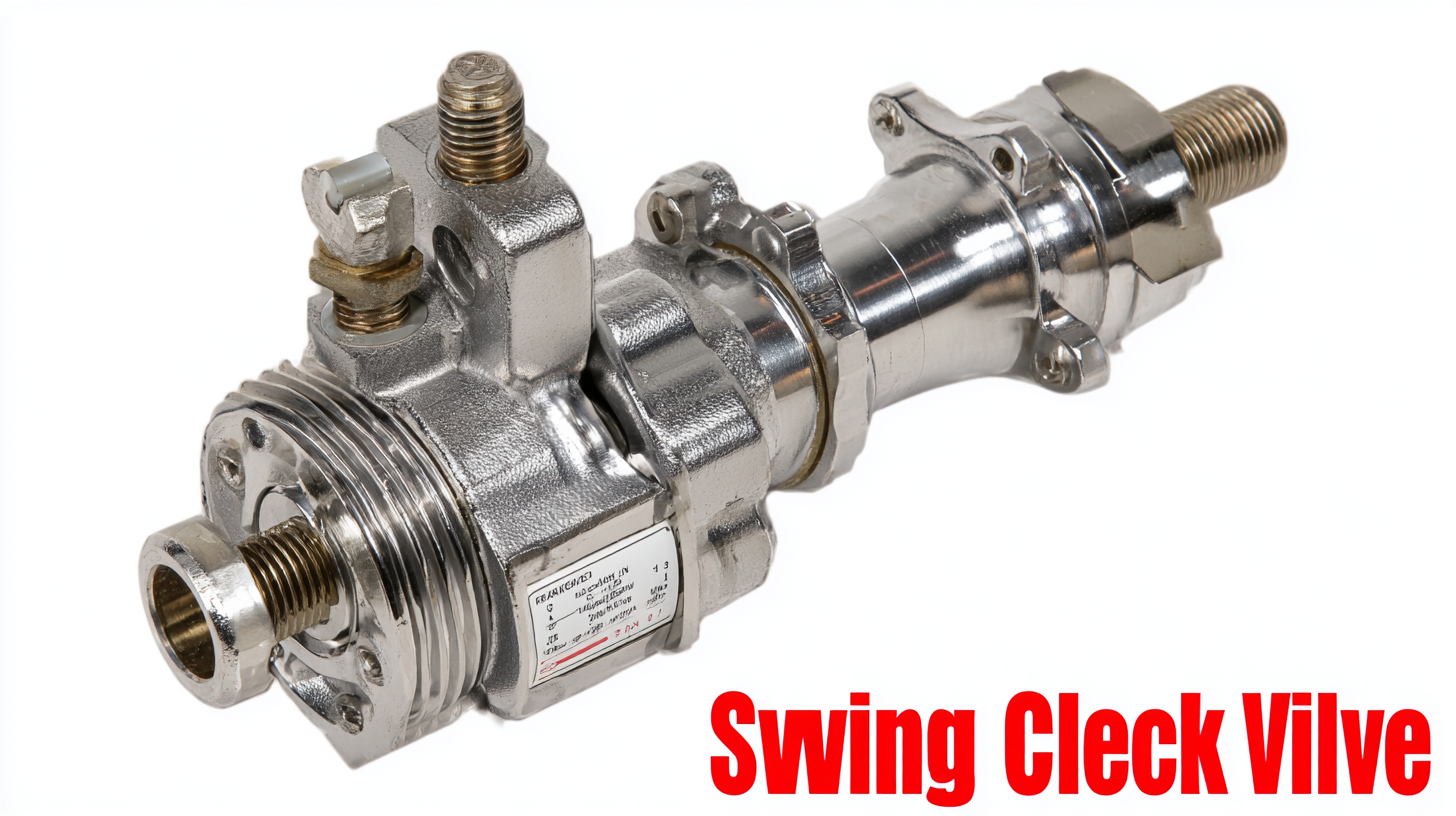

In the realm of fluid dynamics and piping systems, the Swing Check Valve stands out as a crucial component, ensuring that fluids flow in one direction while preventing backflow. This comparative analysis of the top five best swing check valves delves deep into their efficiency and performance metrics, revealing essential insights for engineers and system designers alike.

As industries increasingly prioritize reliability and cost-effectiveness, understanding the nuances between various alternatives becomes imperative. This blog will not only assess the operational efficiency and performance characteristics of each valve but also evaluate their suitability across different applications, highlighting the best options available in the market today.

Whether you're tasked with a new installation or upgrading existing systems, our insights will provide you with the knowledge needed to make informed decisions regarding swing check valves.

Top 5 Performance Metrics for Evaluating Swing Check Valves in Industrial Applications

When selecting swing check valves for industrial applications, understanding performance metrics is crucial for ensuring efficiency and reliability. The top five performance metrics commonly evaluated include flow coefficient (Cv), pressure drop, material compatibility, response time, and maintenance requirements. According to a recent industry report by the Valve Manufacturers Association, a swing check valve with a higher Cv rating (typically above 100) can handle greater flow rates, which is essential in reducing operational costs in large-scale facilities.

Additionally, pressure drop across the valve is a significant consideration, as excessive pressure loss can lead to energy inefficiencies. The American Society of Mechanical Engineers recommends that for optimal performance, the pressure drop should not exceed 10% of the system's total pressure. Material compatibility is also imperative; using valves made from corrosion-resistant materials can significantly extend service life, particularly in harsh environments.

Tip: Regular maintenance checks can greatly enhance the operational lifespan of swing check valves. Ensuring that the sealing components are inspected and replaced as needed can prevent leaks and minimize downtime. Investing in higher-quality valves may have an upfront cost but can result in substantial savings through improved efficiency and lower maintenance expenses over time.

Analysis of Flow Coefficient (Cv) for Optimal Efficiency in Swing Check Valves

When evaluating the performance of swing check valves, the flow coefficient (Cv) serves as a crucial metric in determining efficiency. The Cv value indicates the capacity of the valve to allow fluid flow; the higher the Cv, the more efficient the valve is at passing the fluid under a specified pressure drop. This analysis is essential because it helps in selecting the right valve for specific applications across various industries, ensuring optimal flow rates while minimizing energy costs.

In our comparative analysis of the top five swing check valves, we found that the Cv values varied significantly among models. Some valves demonstrated superior flow characteristics, providing a significant advantage in systems requiring high flow rates. These comprehensive performance metrics allow engineers and system designers to make informed decisions based on the specific requirements of their applications. By focusing on the Cv, stakeholders can not only enhance the efficiency of their fluid systems but also ensure greater reliability and longevity of the equipment used.

Impact of Pressure Drop on the Selection of Swing Check Valves for High-Flow Systems

When selecting swing check valves for high-flow systems, one critical factor to consider is the impact of pressure drop. These valves are designed to prevent backflow, but an improper selection can lead to significant inefficiencies in a system. A high pressure drop can reduce the overall performance of the system, causing pumps to work harder and potentially increasing operational costs. Therefore, it is essential to choose a valve that not only fits the operational demands but also minimizes the pressure drop to maintain system efficiency.

Tip: Always evaluate the pressure drop specifications provided by the manufacturer. Look for swing check valves that offer low resistance to flow to ensure optimal performance in high-flow applications. This choice not only enhances flow rates but also extends the longevity of other system components by reducing stress.

Additionally, taking into account the sizing of the valve is key. Oversized valves can lead to turbulent flow, increasing pressure drop and reducing efficiency. A well-sized valve will balance flow rates and minimize resistance, facilitating smoother operation in high-flow systems.

Tip: Use flow simulation tools to predict performance and select the appropriately sized valve for your system. This proactive approach helps avoid common pitfalls associated with miscalculations in valve sizing.

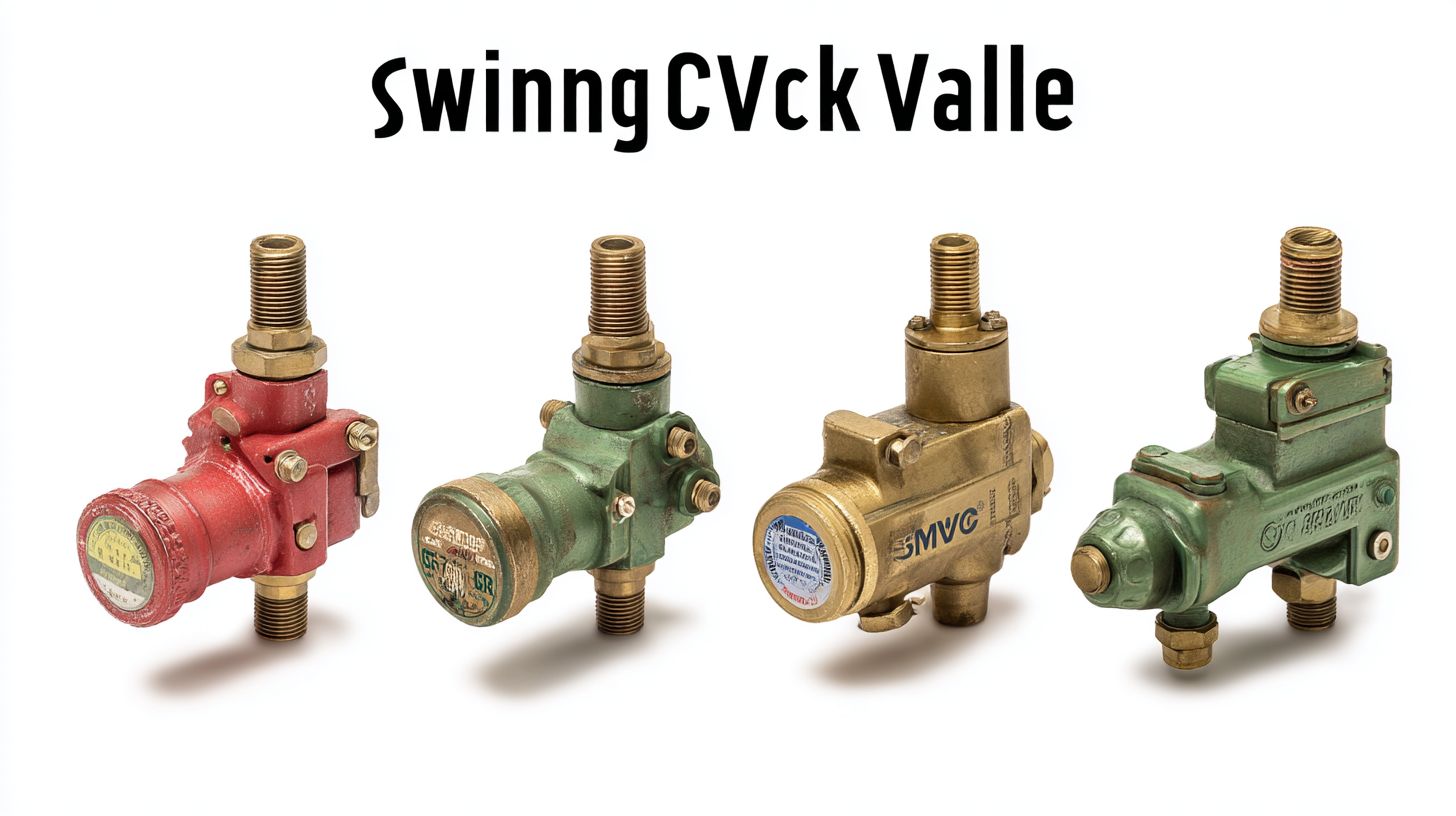

Material Durability: A Key Factor in the Longevity of Swing Check Valves

When evaluating the longevity and reliability of swing check valves, material durability emerges as a crucial factor. According to a report by the American Water Works Association, approximately 80% of valve failures can be attributed to material degradation over time. This deterioration can result from exposure to corrosive fluids, high-pressure environments, and fluctuating temperatures, all of which need to be taken into account when selecting the right valve for a specific application.

Materials such as ductile iron, stainless steel, and bronze are commonly used in the manufacturing of swing check valves due to their exceptional strength and resistance to wear and corrosion. A study conducted by the Valve Manufacturers Association shows that valves made from stainless steel can last up to 25% longer than their cast iron counterparts when exposed to saline environments. This underscores the importance of selecting the appropriate material based on the specific conditions in which the valve will operate. Ensuring material durability not only enhances the performance of swing check valves but also significantly reduces maintenance costs and downtime in industrial applications.

Comparative Study of Installation Flexibility and Maintenance Requirements for Top Valves

In the realm of industrial applications, the installation flexibility and maintenance requirements of valves play a pivotal role in optimizing operational efficiency. The comparative study of the top swing check valves emphasizes the significance of evaluating these aspects when selecting equipment for energy storage systems. Since energy storage technologies are integral to the integration of renewable energy, understanding how various valves can be installed and maintained efficiently can significantly impact the sustainability and performance of energy operations.

Different models of swing check valves often vary in their design and installation parameters. Some may allow for easier installation in curtailed spaces, while others may necessitate more complex arrangements that could increase labor costs and downtime. Additionally, the maintenance requirements of these valves can influence long-term operational economics. By focusing on both the flexibility in installation and the ease of ongoing maintenance, businesses can ensure that they select a valve type that not only meets their performance needs but also aligns with their sustainability goals and operational budget. This careful consideration is essential for fostering a more efficient and resilient energy system.