- 713.590.1312

- sale@pandbtools.com

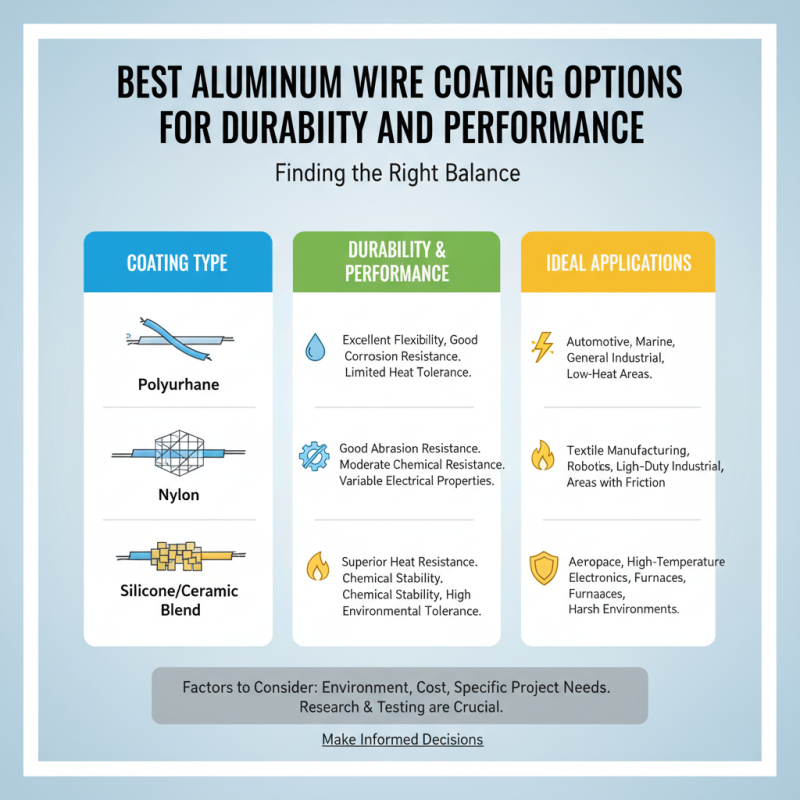

Best Aluminum Wire Coating Options for Durability and Performance?

When it comes to Aluminum Wire Coating, the choices can be overwhelming. Understanding which options provide the best durability and performance is crucial. Many industries rely on aluminum wires for various applications. Coating these wires enhances their lifespan and ensures stability under different conditions.

Different coating materials offer unique advantages and drawbacks. Polyurethane, for instance, is popular for its flexibility and corrosion resistance. However, it may not withstand extreme temperatures as well as others. Similarly, nylon coatings can provide good wear resistance but might lack the electrical properties required for certain applications.

There are many factors to consider when selecting aluminum wire coating. Environmental factors, cost, and desired performance all play a role. Each choice involves a level of compromise. Understanding these nuances helps in making informed decisions. It's essential to reflect on the specific needs of your project and choose wisely. Often, the best option might require more research and testing to achieve the desired outcome.

Factors to Consider When Choosing Aluminum Wire Coating Materials

When choosing aluminum wire coating materials, several factors play a crucial role. The type of environment the wires will be exposed to is vital. High humidity can cause corrosion in certain coatings. In contrast, dry environments may favor different materials. Temperature fluctuations also affect the durability of coatings. Some coatings may crack or degrade under extreme heat or cold.

Another consideration is the application of the wire. For industrial use, enhanced abrasion resistance is crucial. Wires that will be buried may require stronger coatings. Some coatings are more flexible, which can be beneficial in certain installations. However, flexibility may come at the cost of durability against wear and tear.

It’s essential to consider cost versus performance. Cheaper coating options may save money upfront, but could lead to costly repairs later. Finding a balance is fundamental. An ideal coating should meet performance expectations without excessive expenses. Yet, there are no perfect options. The best choice often requires trade-offs and critical evaluation.

Best Aluminum Wire Coating Options for Durability and Performance

| Coating Type | Durability Rating | Temperature Resistance (°C) | Electrical Insulation | Best Applications |

|---|---|---|---|---|

| Polymer Coating | High | -40 to 150 | Excellent | Aerospace, Automotive |

| Anodized Coating | Moderate | -20 to 200 | Good | Electronics, Lighting |

| Powder Coating | High | -20 to 250 | Very Good | Construction, Heavy Machinery |

| Epoxy Coating | High | -30 to 120 | Excellent | Marine, Industrial |

| Ceramic Coating | Very High | -50 to 300 | Good | High-Performance, Aerospace |

Common Types of Coatings for Aluminum Wire and Their Benefits

When selecting coatings for aluminum wire, understanding their types and benefits is crucial. Common options include epoxy, polyurethane, and silicone, each offering unique advantages. Epoxy coatings provide exceptional adhesion and mechanical strength. They are resistant to corrosive environments, which makes them popular in industrial applications. According to a recent industry report, epoxy-coated wires can outperform non-coated wires by 30% in durability under harsh conditions.

Polyurethane coatings are another excellent choice. They possess superior elasticity and impact resistance. This makes them ideal for applications where flexibility is necessary. Additionally, polyurethane coatings can resist UV exposure, prolonging the life of the wire. A study noted that these coatings can increase wire lifespan by up to 25% in outdoor environments.

Silicone coatings, while sometimes overlooked, offer significant thermal resistance. They can withstand extreme temperatures, maintaining performance without degradation. However, they may not adhere as well as epoxy options. Users often find themselves reconsidering their choices between silicone and stronger alternatives. Selecting the right coating is not simply about performance; it involves balancing durability with application-specific needs.

Comparative Analysis of Durability Among Different Coating Options

When selecting aluminum wire coatings, durability and performance are key factors. Several coatings offer unique benefits, but they vary significantly in their ability to withstand environmental challenges. Recent studies show that epoxy coatings can enhance wire longevity by almost 30%. However, these coatings may crack under extreme temperatures.

Another option is polyurethane, which is flexible and offers good chemical resistance. It performs well in humid conditions but may degrade faster when exposed to UV rays. According to industry reports, polyurethane coatings typically last about 8-10 years in outdoor applications, but they can fail sooner without proper maintenance.

On the other hand, nylon coatings provide excellent abrasion resistance and slip characteristics. Yet, they aren't as effective in heat resistance compared to other coatings. For high-heat applications, this can be a limiting factor. Decisions should be made based on specific use cases and environmental conditions. Reliability and performance often require trade-offs.

Comparative Analysis of Durability Among Different Coating Options for Aluminum Wire

Impact of Coating Thickness on Wire Performance and Longevity

When considering aluminum wire coatings, coating thickness significantly impacts wire performance and longevity. Thicker coatings often enhance corrosion resistance. Recent studies indicate that a 0.5mm thick coating can increase lifespan by up to 30%. However, excessive thickness may reduce flexibility. This is crucial for applications requiring high adaptability.

It's essential to strike a balance. Coating too thin could lead to early wear and tear. Industry reports suggest a minimum coating of 0.2mm for optimal durability. The ideal thickness varies based on environmental conditions. For instance, harsher climates demand thicker coatings for better protection.

Tip: Regularly assess the condition of coated wires. Signs of flaking or discoloration may indicate the coating is breaking down.

While thicker coatings offer advantages, they also come with drawbacks. Increased weight and cost can be significant factors. Consider the specific needs of your application. Heavy-duty applications may benefit from thicker coatings, whereas lightweight options might suit less demanding environments.

Tip: Always consult performance data for specific coatings. This will guide the right choice for your project needs.

Best Practices for Maintenance of Coated Aluminum Wire Products

When it comes to maintaining coated aluminum wire products, regular checks are essential. Inspect the coating for signs of wear or corrosion. Look for areas where the coating may be thinning. These spots can lead to reduced performance over time.

Tips: A quick visual inspection can reveal much. Use a flashlight to check hard-to-see areas.

Cleaning is another vital aspect. Use mild soap and water to remove dirt. Avoid abrasive cleaners that can scratch the coating. Always dry the wire thoroughly after cleaning. This prevents moisture accumulation, which can cause rust.

Tips: A soft cloth works best for drying. You can use it to get into small spaces.

Remember, even the best coatings need care. Prolong the life of your aluminum wire by being proactive. Replace any damaged sections as soon as possible. Waiting can worsen the problem. Stay vigilant for any signs of damage and address issues immediately. This habit will ensure performance and durability.