- 713.590.1312

- sale@pandbtools.com

2025 Market Insights: Elevating Efficiency with the Best Knife Gate Valve Solutions

In the evolving landscape of industrial applications, the demand for Knife Gate Valves has surged, driven by their critical role in enhancing operational efficiency and reliability. According to a recent market report by MarketsandMarkets, the global knife gate valve market is projected to reach USD 3.1 billion by 2025, growing at a CAGR of 4.5% from 2020. This growth is attributed to the increasing need for efficient fluid control in various sectors, including wastewater treatment, mining, and chemical processing. As industries strive for higher operational efficiency, the importance of investing in high-quality Knife Gate Valve solutions becomes paramount. With China's prominent manufacturing capabilities, offering world-class quality and innovation, the market is set to witness a significant transformation, leading to enhanced performance and sustainability in fluid management systems.

The Rise of Chinese Manufacturers in the Knife Gate Valve Market

The knife gate valve market is witnessing a significant transformation, particularly with the rise of Chinese manufacturers. According to recent industry reports, the global industrial valves market is poised for substantial growth, expected to reach a remarkable USD 16.3 billion by 2032. This surge is driven by increasing demand across various sectors, including water treatment and mining, where efficient and reliable valve solutions are paramount.

Chinese manufacturers have emerged as key players in this landscape, leveraging advancements in production technology and competitive pricing. As they continue to enhance their capabilities, market share for Chinese companies in the knife gate valve segment is projected to grow significantly. This trend aligns with the broader shift in the industrial valve market, where diverse materials and applications are driving innovation. Notably, the increasing prevalence of stainless steel and cast iron valves reflects the industry's focus on durability and corrosion resistance, essential factors for operational efficiency.

With these dynamics at play, industry stakeholders must stay informed about emerging trends and opportunities within the evolving knife gate valve sector, especially as Chinese manufacturers elevate their presence and offerings in the global marketplace.

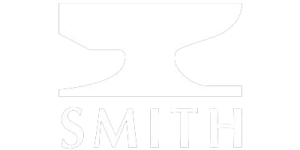

Innovative Technologies Driving Efficiency in Knife Gate Valve Solutions

The landscape of industrial applications is evolving rapidly with the advent of innovative technologies that are significantly enhancing the efficiency of knife gate valve solutions. As industries seek to optimize their operational processes, knife gate valves are emerging as a critical component in controlling the flow of liquids and slurries. One of the key advancements is the integration of smart sensors that provide real-time data on valve performance. These sensors allow for precise monitoring and remote control, enabling operators to make informed decisions and reducing the risk of downtime due to valve malfunctions.

In addition to smart technology, the utilization of advanced materials is revolutionizing the design and durability of knife gate valves. The development of corrosion-resistant composites not only extends the lifespan of these valves but also improves their performance in harsh environments. This innovation helps industries to minimize maintenance costs and enhance operational reliability. As we look towards 2025, it is clear that these technological advancements will continue to drive efficiency, making knife gate valves an indispensable solution in various sectors ranging from wastewater management to mining operations.

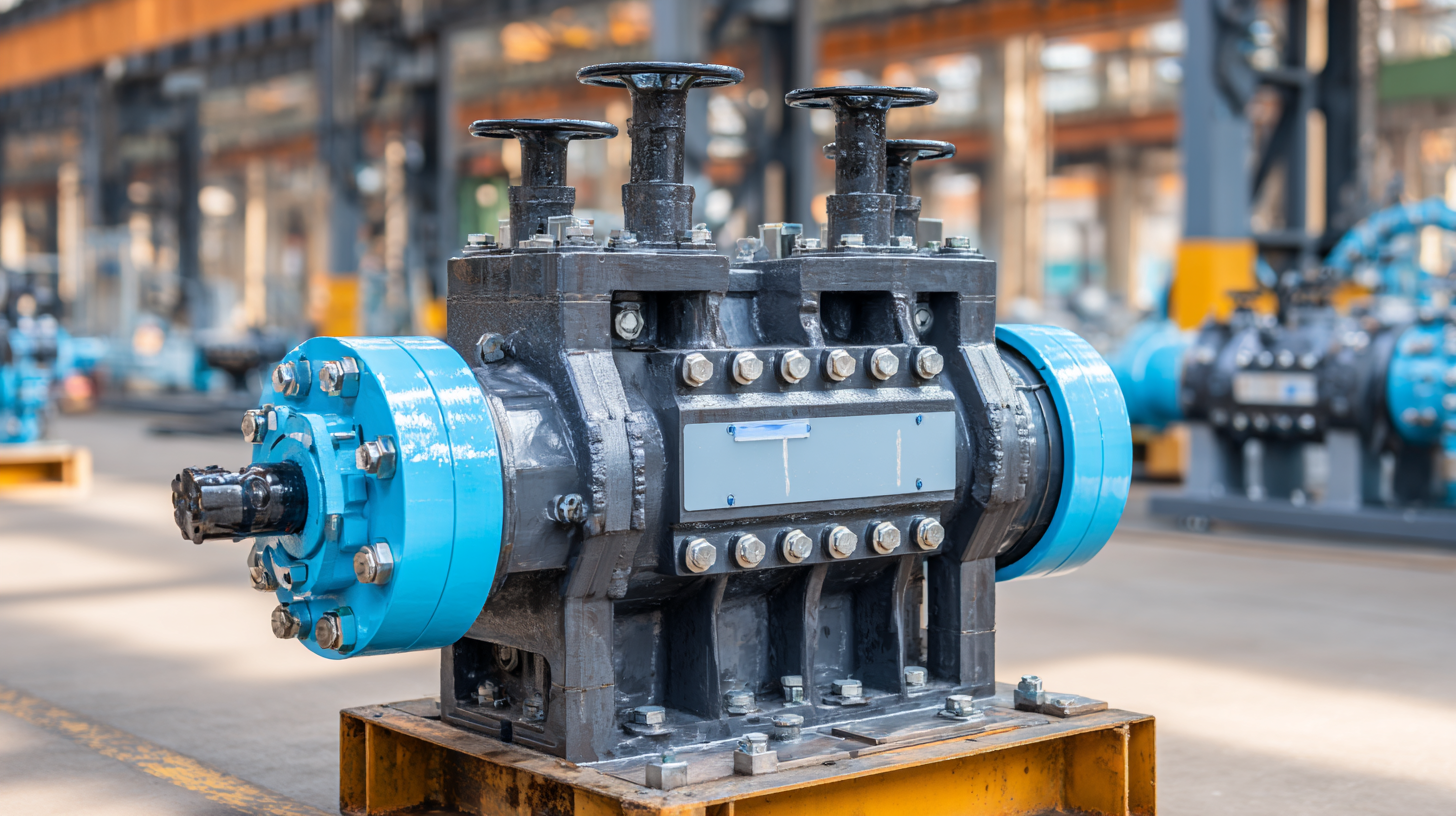

Global Demand for High-Quality Knife Gate Valves: A Closer Look

The global demand for high-quality knife gate valves is surging as industries seek to enhance operational efficiency. According to recent market trends, the industrial valve sector is projected to witness substantial growth, driven by the increasing need for reliable and efficient fluid control solutions. With the projected value of the industrial valve market estimated to reach $121.67 billion by 2024, knife gate valves are emerging as a pivotal component in various applications, particularly in sectors like mining, oil and gas, and wastewater management.

In this context, manufacturers are focusing on innovation and the provision of durable solutions that meet the stringent requirements of diverse industries. For instance, the performance of advanced knife gate valves, such as those utilized in tailings lines, underscores their importance in maintaining operational integrity over extended periods. As industries evolve, the emphasis on high-quality valve solutions will be crucial in supporting sustainability and efficiency objectives, marking a significant shift towards prioritizing reliable equipment that enhances overall productivity.

Sustainability Practices in Knife Gate Valve Production

The production of knife gate valves is evolving towards more sustainable practices as the industry recognizes its environmental responsibilities. According to a report by the Global Valve Market Research, over 40% of manufacturing firms are now adopting eco-friendly materials and production processes. This shift not only reduces the carbon footprint but also ensures that the valves comply with increasingly stringent environmental regulations. For instance, the integration of recycled materials in valve bodies can lower energy consumption by up to 30%, showcasing how even small changes can lead to significant efficiencies.

Furthermore, advancements in technology are enabling manufacturers to optimize their operations. The Annual Industrial Sustainability Report indicated that companies implementing smart manufacturing techniques—such as predictive maintenance and energy management systems—have seen an average reduction of 25% in waste generation during production. These innovations not only bolster productivity but also enhance the longevity of knife gate valves, ultimately aligning with the industry's goals of durability and efficiency. As the market continues to demand high-quality, sustainable products, knife gate valve solutions that prioritize eco-friendly practices are positioned to lead the way in the coming years.

Market Trends and Predictions for 2025 in Valve Solutions Industry

As we look ahead to 2025, the valve solutions industry is poised for transformative changes driven by advancements in technology and evolving market demands. One significant trend is the growing emphasis on automation and smart technologies. The integration of IoT-enabled systems within knife gate valves allows for enhanced monitoring and control, leading to improved efficiency and reduced operational costs. Companies that invest in these innovative solutions are likely to gain a competitive edge, as they can offer clients superior reliability and performance.

Additionally, sustainability increasingly shapes market dynamics. The demand for eco-friendly valve solutions is rising, as industries strive to minimize their environmental footprint. Manufacturers are responding by developing knife gate valves with materials that are not only durable but also recyclable. This shift towards sustainability not only aligns with global regulations but also meets the expectations of a more environmentally conscious consumer base. As we approach 2025, those companies that prioritize efficiency and eco-friendliness in their valve solutions will be well-positioned to succeed in an ever-evolving market landscape.