- 713.590.1312

- sale@pandbtools.com

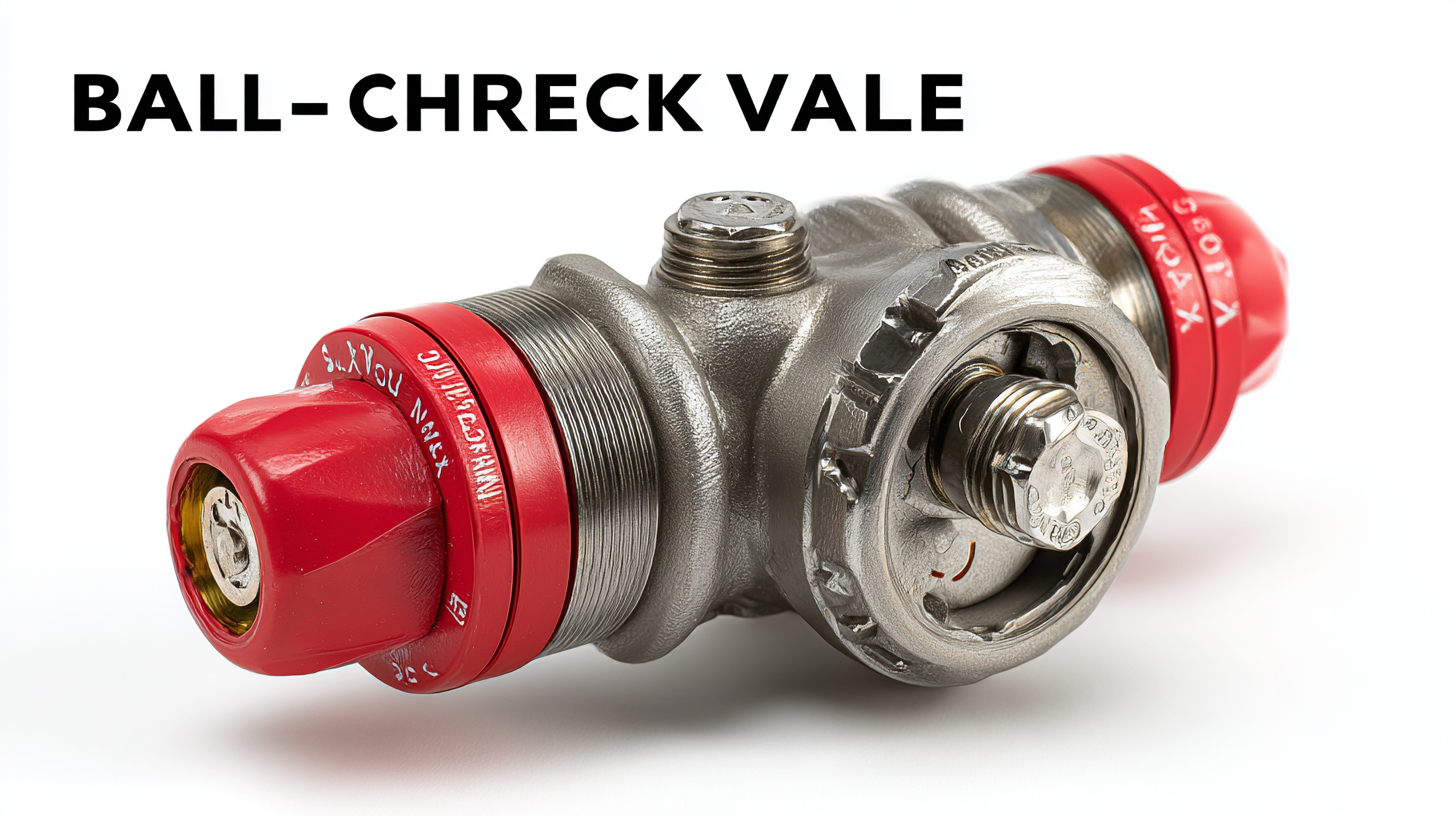

Maximizing Efficiency: The Advantages of Utilizing Best Ball Check Valves in Industrial Applications

In the landscape of industrial applications, ensuring optimal efficiency is paramount, and one component that significantly contributes to this goal is the Ball Check Valve. According to a report by MarketsandMarkets, the global valve market is projected to reach USD 92.5 billion by 2025, with check valves, particularly ball check valves, playing a critical role in various sectors such as water treatment, oil and gas, and chemical manufacturing. These valves provide a reliable solution for preventing backflow, thereby enhancing system performance and reducing downtime. With their ability to withstand high pressure and flow rates, ball check valves are essential for maintaining the integrity of industrial processes. As industries strive for greater efficiency and sustainability, understanding the advantages and applications of ball check valves becomes crucial for informed decision-making and improved operational outcomes.

Benefits of Best Ball Check Valves for Fluid Control Efficiency

In industrial applications, fluid control is critical for maintaining efficiency and safety. Best ball check valves provide a reliable solution for preventing backflow, ensuring that fluids flow smoothly in one direction. This capability is particularly important in systems where the integrity of the fluid path cannot be compromised. The design of ball check valves allows them to respond quickly to changes in pressure, making them ideal for dynamic environments where operational conditions can fluctuate.

Moreover, the installation of best ball check valves contributes significantly to reducing maintenance costs. Since they require less frequent replacements and repairs compared to other types of check valves, they can lead to long-term savings for businesses. Their durable construction minimizes the risk of leaks and failures, allowing industries to operate with increased confidence. By leveraging the advantages of best ball check valves, companies can achieve greater fluid control efficiency, leading to optimized processes and enhanced overall productivity.

Key Features of Best Ball Check Valves in Industrial Settings

In industrial applications, best ball check valves offer a range of features that significantly enhance operational efficiency. One key advantage is their ability to prevent backflow, ensuring that fluids can only flow in one direction. This crucial characteristic safeguards equipment and maintains system integrity, especially in processes involving sensitive materials. Additionally, these valves are designed for durability, with materials that resist corrosion and wear, thus prolonging their lifespan and reducing maintenance costs.

When selecting best ball check valves, consider the flow rate and pressure conditions of your specific application. Choosing the right valve size can prevent issues such as excessive pressure drops or turbulence, which can affect overall system performance. It's also important to evaluate the sealing mechanism; high-quality valves provide reliable sealing, minimizing the risk of leaks and ensuring consistent operation.

**Tip:** Implement regular inspections and maintenance schedules for your check valves to identify wear and prevent failures before they occur. **Tip:** Ensure compatibility between the valve materials and the fluids being handled to avoid corrosive damage that can lead to premature valve failure. This proactive approach will help maximize the longevity and efficiency of industrial systems utilizing best ball check valves.

Comparative Analysis: Best Ball Check Valves vs. Traditional Check Valves

In the realm of industrial applications, the choice of check valves significantly influences system efficiency and reliability. Traditional check valves, while widely used, often face challenges such as leakage and maintenance issues. A report by Research and Markets indicates that nearly 30% of valve failures in industrial settings can be attributed to the limitations of traditional designs, leading to unexpected downtimes and increased operational costs. This is where best ball check valves exhibit a clear advantage, providing superior sealing capabilities and operational longevity.

Best ball check valves utilize a spherical ball design that offers a more effective sealing surface compared to traditional flap or swing designs. Data from the Valve Manufacturers Association reveals that these innovative valves can reduce flow resistance by up to 15%, leading to enhanced flow rates and energy efficiency. Additionally, their simple, robust design minimizes the risk of jamming and maintenance interventions, translating to lower total cost of ownership. As industries seek to optimize performance and reduce operational risks, the transition to best ball check valves is not just a trend, but a strategic move backed by compelling data.

Applications of Best Ball Check Valves Across Various Industries

In industrial settings, best ball check valves are pivotal for enhancing operational efficiency across a wide range of applications. One notable advantage of these valves is their ability to prevent backflow, ensuring that liquids and gases flow in only one direction. According to a report by the Fluid Control Institute, improper fluid management can lead to energy losses exceeding 20%, highlighting the importance of reliable check valves in reducing operational costs and increasing productivity.

These valves find extensive use in industries such as water treatment, oil and gas, and pharmaceuticals. In water treatment facilities, for instance, they safeguard against contamination by preventing reverse flow that could compromise water quality. The Oil & Gas Journal emphasizes that implementing best ball check valves can improve system reliability and reduce maintenance costs by up to 30%, thus allowing for uninterrupted operations. Furthermore, in the pharmaceutical industry, where compliance with stringent regulations is critical, these valves ensure the integrity of high-value fluids, thereby protecting both product quality and company profits.

Guidelines for Selecting the Right Best Ball Check Valve for Your Needs

When it comes to selecting the right best ball check valve for your industrial applications, several key factors come into play. First and foremost, you’ll want to assess the specific fluid type and temperature that the valve will encounter. Different materials can withstand varying levels of corrosiveness and pressure, so choosing a valve made from suitable materials, such as bronze, stainless steel, or PVC, is crucial for longevity and performance. Additionally, ensure that the valve’s size aligns with your system's specifications to prevent issues related to flow rate and pressure drop.

Another important guideline is to consider the installation environment. If your application occurs in a high-vibration or dynamic setting, selecting a check valve equipped with resilient features can make a significant difference in reliability. Furthermore, evaluate operational ease—valves that provide quick access for maintenance will save time and reduce downtime in your operations. By understanding these factors and aligning them with your operational needs, you can maximize the benefits of using best ball check valves in your industrial setup.